Leather Town and the building of the Solent Forts

John Towlerton Leather, a civil engineer of great renown, was the main contractor of the massive Portland Breakwater in Dorset. In Hampshire, he built the Spithead Forts, as well as a 2¼ million pound extension to Portsmouth Dockyard. He was offered and accepted the main contract in 1861 for building the Solent forts and all the arrangements to construct them. His agent was W.Hill and manager Edward Pease Smith. His construction yard was established at Stokes Bay on a site known as White’s Yard, east of the present GAFIRS lifeboat Station, close to Stokes Bay pier. This site later became the Submarine Mining Establishment and still later the R.E. School of Electric Lighting.

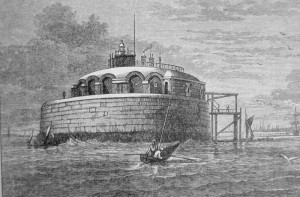

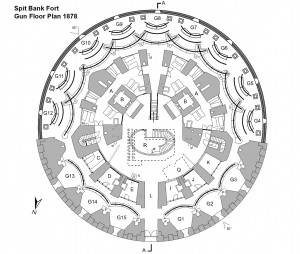

The forts were designed by Captain E H Steward R.E. of Col. Jervois’ Royal Engineer staff. Experiments had shown that granite alone could not withstand bombardment and the plans were altered to include iron armour on an iron superstructure. The forts were originally to be built on shoals in the Solent, at:- Horse Sand, No Man’s Land, Spit (Bank) Sand, Sturbridge and one between Horse Sand and Portsea Island. This last fort was dropped quite early, at Sturbridge it was abandoned in 1863 because of poor strata of soil to build foundations, at Spit Sand it was moved 600 yards S/W for the same reason. A new fort was suggested and started at Ryde Sand but this was abandoned because of poor strata of soil to build foundations. In 1869 another fort built was built at St. Helen’s Point on the Isle of Wight. Leather also had the contract for building this fort’s foundation.

Sir John Hawkshaw, was consultant for the foundations. Sir John had advised on the construction of the Severn tunnel and the Hungerford and Cannon St railway bridges in London. He proposed laying a prepared stone and concrete ring foundation on the sea bed at a cost of £163,000, despite the Defence Committee worrying that heavy seas would prevent accurate positioning of the stone blocks.

The Government and the Opposition were showing concern over; the cost, the needs, the sighting, and construction of the forts and the work was postponed for about two years.

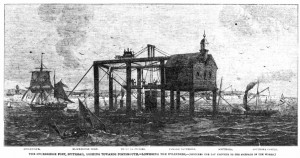

Some work did actually continue, the War Department supervised the checking and surveying of the strata of seabed for the foundations of the forts. Temporary platforms were built over the proposed sites, and each provided with a lighthouse.

Huge wrought iron cylinders six feet in diameter were lowered upright down onto the sea bed, then divers went inside and dug out the centre so the cylinder sunk slowly a bit at a time. This job must have been extremely difficult, cold, wearing very heavy divers suits and working in the pitch black!! The material dug out was analysed and a picture of the strata of the sea bed was obtained. As the tube sank into the sea bed extra cast iron tubes were added to the top. The final depth was 55 feet below the sea bed when the divers had to give up, because the air pressure in their helmets was three times that of the atmosphere above sea level.

The information for possible foundations gained from sinking the cylinders confirmed the site of some forts and discounted others. Cylinders were then sealed at the bottom and much later this was bored through to a depth of about 500 feet where they found a supply of fresh water.

In late 1863 Leather started work on building the construction platforms he would need to lay the fort’s foundations. He added to the original platforms on each site, by using capstans to screw large piles into the seabed, each pile had a cast iron screw head. On these piles he built large platforms covering the whole site of the forts foundations. Planking was laid for roadways to take a circular railway for the travelling steam cranes. The light house was maintained on site by Mr Leather’s men who would regularly check and trim the wicks of the lighthouse lamps. Several huts were built for the 50 to 60 men that would be working on site, this would include 12 divers.

J.T. Leather’s contract at Stokes Bay included making concrete blocks, provision of steam engines, steam cranes, pile drivers, the erection of a shipping pier, special barges for transport and circular stages for the construction work. This was all to be done under the general supervision of the Royal Engineers Department. A large complex of buildings was established at White’s Stokes Bay yard. Here thousands on concrete blocks that were needed in the construction were made. At the yard was a cement mill, cement stores, blacksmiths, with a village of workshops. Other buildings were constructed to support all the work including a ‘Shanty Town’ where many of the workmen lived. It became known as ‘Leather Town’.

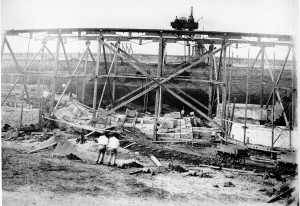

The works had railway lines crossing the site in all directions and also a junction with the Stokes Bay Railway company line. Overhead railways were also built, worked by great and powerful steam cranes for moving great blocks of stone.The scene would be similar to this photo of Leather’s construction site at the Portsmouth Dockyard extension.

A stout pier was built out into Stokes Bay from the southern edge of the works, with a double railway line and a steam crane on it. Portland and Penhryn Stone was delivered to Stokes Bay by sea and Runcorn stone arrived at the site by rail. The crane on the pier not only unloaded the rough cut stone onto the site, but also delivered finished stone from site to lighters and barges which were pulled out to the fort building site by steam tugs. Each stone or concrete block moved weighed between 3 to 8 tons. On a part of the site, a section of ground was cemented over and laid out as a “Drawing board”.

|

|

Shaped and trimmed stones were laid out here as they would be underwater, then numbered and marked in coloured lines. Using these numbers and the coloured lines, the divers were then able to fix them in their correct place on the fort site. Tugs moved the lighters (large barges) heavily laden with stone out to the first site from Stokes Bay, to build the Horse Sand Fort, No Man’s Land Fort and Spit Bank (Spitsand) Fort.

Concrete blocks were used in the foundations of the forts where the least strength was needed. They were made in the Stokes Bay works from Stokes Bay shingle and cement manufactured on the Isle of Wight. Hundreds of blocks were made by being moulded in wooden boxes, hardened off then stacked for use.

In 1864 when the main work was re-started, the Stokes Bay site had, waiting on site, 15,000 tons of concrete blocks and 7,000 tons of prepared stone.

The stone or concrete blocks were checked for fit, trimmed, marked and taken from Stokes Bay to site by barge. The crane on the platform then lifted each block out of the barge and lowered it into position under direction of divers working on the sea bed.

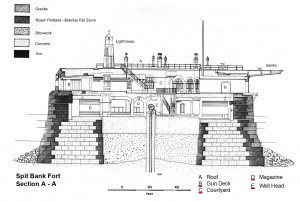

The forts foundations were built like giant “doughnuts”. The core of the ring was constructed with the concrete blocks, and the inner and outer surfaces were then were faced with stone blocks. For strength a final layer of granite blocks was built on the outer stone face, this gave a final wall thickness of 59 feet.

At Spit Bank the centres of the rings were then filled in, to 10 feet from the top with clay and shingle. The last 10 feet was filled in with concrete, finishing 1½ feet above high water. On these foundations the basement floor of the forts were built, the top of the basement finished about 11 feet above the high-water mark.

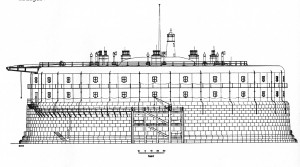

The first stones were laid on the Horse and No Man’s shoals in March 1865 and on the Spit Bank exactly two years later. The work started seventeen feet below the low water mark and continued until the top of the fourteenth course had been reached, in January 1868. At No Man’s Land, the foundations had to go some ten feet deeper, because of the soft ground. With all the forts there were a few problems in keeping the work level and at Spit Bank this was corrected at the eighth course. When the lower parts were finished, there was a considerable delay before the iron superstructure and armour was designed and fitted. The ironwork was supplied by Fairbairn Engineering Company. The armour-plate iron for the shields was supplied by Cammell and Co. of Sheffield.

In 1872 the first fort was ready to accept the iron work to enable the fort to be completed. Fairbairn’s contract for Horse Sand and No Man’s Land was a structure of two floors to carry 49 guns for each fort. This frame work also had to take the weight of all the armour plating which was to be hung on the outer face of the fort and also the weight of the concrete roof.

Each construction was a huge skeleton of ironwork weighing 2,400 tons and took 14 months to build, then it was erected at Fairbairn’s works site to make sure it all fitted exactly. It was taken apart and moved by rail to Stokes Bay and shipped out to the fort and erected in its final position.

The work was supervised locally by Mr. H. M. Harman Fairbairn Company’s engineer. Apparently it all fitted exactly “…and not a farthing of expense had to be incurred in correction”. The iron work covered nearly two thirds of the area of the foundations and was a massive and impressive construction.

Boring for fresh water began on 21 July 1873 at No Man’s Land Fort and on 31 May 1877 at Spit Bank Fort. This was done with tubing 18 inches in diameter and 1 inch thick narrowing to 15 inches of wrought iron shod with steel. Water was found at a depth of 571 feet on the No Man’s Land site and at 128 feet at Spit Bank Fort, where 23,000 gallons per day was available at No Man’s Land and 14,000 gallons per hour was available at Spit Bank Fort . The core samples are now stored at Fort Brockhurst, of the Gosport Advanced Lines.

Pulleys and tackle were used to put the guns in place before the main iron shields were placed on the outside of the fort. The dates the forts were completed:- Spit Bank in 1878, St. Helen’s in 1879 and both Horse Sand and No Man’s Land in 1880.

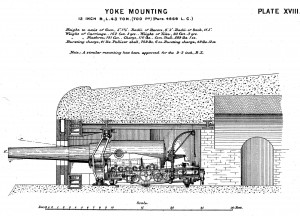

The armament of the forts was revised many times. The largest gun to be fitted to Horse Sand Fort and No Man’s Land Fort was the 12-inch Breech loading gun of 43 tons.

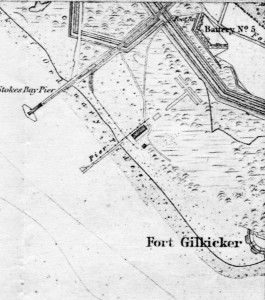

The War Office approached Mr Leather during the building of the sea forts and asked if he would complete Fort Gilkicker. The previous contractor Jaz Goslin failed after only six months work. Mr Leather agreed and started in 1865.